DTC P0796 Pressure Control Solenoid "C" Performance (Shift Solenoid Valve SL3) |

for Preparation Click here

DESCRIPTION

The TCM uses the vehicle speed signal and signals from the transmission speed sensors (NC, NT) to detect the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear).Then the TCM compares the actual gear with the shift schedule in the TCM memory to detect mechanical problems of the shift solenoid valves and valve body.

| DTC Code | DTC Detection Condition | Trouble Area |

| P0796 | Either condition is met (2-trip detection logic):

|

|

MONITOR DESCRIPTION

The TCM commands gear shifts by turning the shift solenoid valves on and off. According to the input shaft speed, intermediate (counter) shaft speed and output shaft speed, the TCM detects the actual gear (1st, 2nd, 3rd, 4th, 5th or 6th gear). When the gear commanded by the TCM and the actual gear are not the same, the TCM illuminates the MIL and stores the DTC.INSPECTION PROCEDURE

| 1.CHECK DTC OUTPUT (IN ADDITION TO DTC P0796) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the intelligent tester on.

Enter the following menus: Powertrain / ECT / DTC.

Read the DTCs using the intelligent tester.

Result Result Proceed to P0796 and other DTCs are output A Only P0796 is output B

- HINT:

- If shift solenoid valve SL3 is stuck off, DTCs for several shift solenoid valves including the malfunctioning shift solenoid valve will be stored.

|

| ||||

| A | |

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (RUNNING TEST) |

- NOTICE:

- This test should always be performed with at least 2 people.

Warm up the engine.

Turn the ignition switch off.

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the intelligent tester on.

Enter the following menus: Powertrain / ECT / Active Test.

According to the display on the intelligent tester, perform the Active Test.

- HINT:

- Comparing the gear commanded by the Active Test with the actual gear enables confirmation of the problem (Click here).

ECT Tester Display Test Part Control Range Diagnostic Note Control the Shift Position Operate the shift solenoid valves and set each shift position - Press "→" button: Shift up

- Press "←" button: Shift down

Can be used to check the operation of the shift solenoid valves.

A 10-second interval is required between gear changes.

Do not down-shift at high speeds. Doing so will damage the automatic transaxle.

[Vehicle Condition]- 50 km/h (30 mph) or less

- NOTICE:

- This test can be conducted when the vehicle is stopped.

- When shifting gears using the Active Test function, do not operate the accelerator pedal for 2 seconds before and after shifting gears.

- HINT:

- The gear commanded by the TCM is shown in the Data List / Shift Status display on the intelligent tester.

Check the vehicle speed and gear when the engine speed is 1000 rpm.

- HINT:

- Because the torque converter clutch has not engaged, it may be difficult to obtain the speeds specified in 4th, 5th and 6th gear, however a difference of speed should still be evident following each gear change.

Standard 1st 2nd 3rd 4th 5th 6th 8 to 12 km/h (5 to 7.5 mph) 15 to 19 km/h (9.3 to 11.8 mph) 21 to 25 km/h (13.0 to 15.5 mph) 31 to 35 km/h (19.3 to 21.7 mph) 44 to 48 km/h (27.3 to 29.8 mph) 52 to 56 km/h (32.3 to 34.8 mph)

Compare the TCM commanded gear and the actual gear.

- Result:

System Condition TCM Gear Shift Command Proceed to 1st 2nd 3rd 4th 5th 6th Malfunction Shift solenoid valve SL1 Stuck ON 1st 2nd 3rd 4th 4th 4th A Stuck OFF N*1 N*1 N*1 N*1 5th 6th Shift solenoid valve SL2 Stuck ON 4th 4th 4th 4th 5th 6th B Stuck OFF 1st 2nd 3rd 1st N*1 N*1 Shift solenoid valve SL3 Stuck ON 2nd 2nd 3rd 4th 5th 6th C Stuck OFF 1st 1st 3rd 4th 5th N*1 Shift solenoid valve SL4 Stuck ON 3rd 3rd 3rd 4th 5th 5th D Stuck OFF 1st 2nd 1st 4th N*1 6th Shift solenoid valve SLT Stuck ON N*2 N*2 N*2 N*2 N*2 N*2 E Stuck OFF*3 1st 2nd 3rd 4th 5th 6th

- HINT:

- *1: Neutral

- *2: If shift solenoid valve SLT is stuck on, the line pressure will be low. Therefore, the amount of torque that can be transmitted by each gear is lower than the normal limit. When the engine power exceeds this lowered limit, the engine speed will increase freely.

- *3: When shift solenoid valve SLT is stuck off, gear shifting is normal.

|

| ||||

|

| ||||

|

| ||||

|

| ||||

| A | ||

| ||

| 3.INSPECT SHIFT SOLENOID VALVE SL3 |

Remove shift solenoid valve SL3.

|

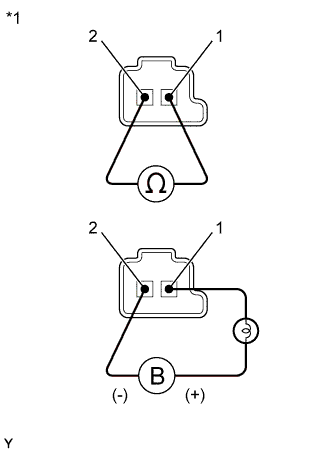

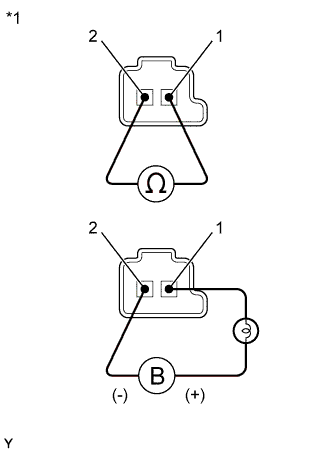

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 5.0 to 5.6 Ω

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition Specified Condition - Battery positive (+) with a 21 W bulb → Terminal 1

- Battery negative (-) → Terminal 2

Valve moves and makes an operating noise - Battery positive (+) with a 21 W bulb → Terminal 1

| *1 | Component without harness connected (Shift Solenoid Valve SL3) |

|

| ||||

| OK | |

| 4.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (Click here).

- OK:

- There are no foreign objects on any valve.

|

| ||||

| OK | ||

| ||

| 5.INSPECT SHIFT SOLENOID VALVE SL3 |

Remove shift solenoid valve SL3.

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 5.0 to 5.6 Ω

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition Specified Condition - Battery positive (+) with a 21 W bulb → Terminal 1

- Battery negative (-) → Terminal 2

Valve moves and makes an operating noise - Battery positive (+) with a 21 W bulb → Terminal 1

| *1 | Component without harness connected (Shift Solenoid Valve SL3) |

|

| ||||

| OK | |

| 6.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (Click here).

- OK:

- There are no foreign objects on any valve.

|

| ||||

| OK | ||

| ||