RADIATOR > ON-VEHICLE INSPECTION |

for Preparation Click here

| 1. INSPECT RADIATOR CAP SUB-ASSEMBLY |

|

- CAUTION:

- To avoid the danger of being burned, do not remove the radiator cap while the engine and radiator are still hot, as fluid and steam can be blown out under pressure.

Measure the valve opening pressure.

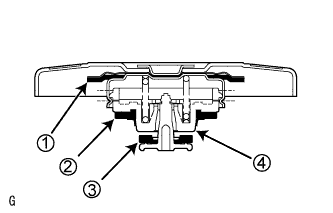

If there are water stains or foreign matter on rubber packing 1, 2 or 3, clean it by using water and finger scouring.

Check that rubber packing 1, 2 and 3 are not deformed, cracked or swollen.

Check that rubber packing 3 and 4 are not stuck together.

Apply engine coolant to rubber packing 2 and 3.

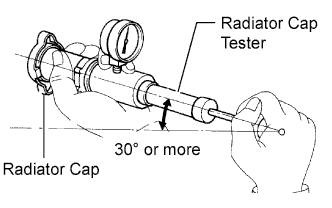

Prepare a radiator cap tester, and tilt it more than 30°.

Pump the cap tester several times, and check the maximum pressure*.

- Pumping speed:

- 1 pump per second

- HINT:

- *: Even if the cap cannot maintain the maximum pressure, it is not a defect.

- Standard Judgment Criterion:

Item Specified Condition Standard value

(for brand-new cap)93 to 123 kPa (1.0 to 1.3 kgf/cm2, 13.5 to 17.8 psi) Minimum standard value

(after using cap)78.5 kPa (0.8 kgf/cm2, 11.4 psi)

| 2. INSPECT FINS FOR BLOCKAGE |

Check that the radiator and condenser are not blocked with leaves, dirt, or insects. Clean the hose connections.

If the fins are blocked, wash them with water or a steam cleaner.- NOTICE:

- If the distance between the steam cleaner and core is too close, the fins may be damaged.

- Keep the following injection distance.

- Standard injection distance:

Injection Condition Injection Pressure 300 mm (11.8 in.) 2942 to 4903 kPa (30.0 to 50.0 kgf/cm2, 427 to 711 psi) 500 mm (19.7 in.) 4903 to 7845 kPa (50.0 to 80.0 kgf/cm2, 711 to 1138 psi)

- If the fins are bent, straighten them with a screwdriver or pliers.

- Never apply water directly onto the electric components.

Dry the fins with compressed air.