DTC P2759 Torque Converter Clutch Pressure Control Solenoid Control Circuit Electrical (Shift Solenoid Valve SLU) |

for Preparation Click here

DESCRIPTION

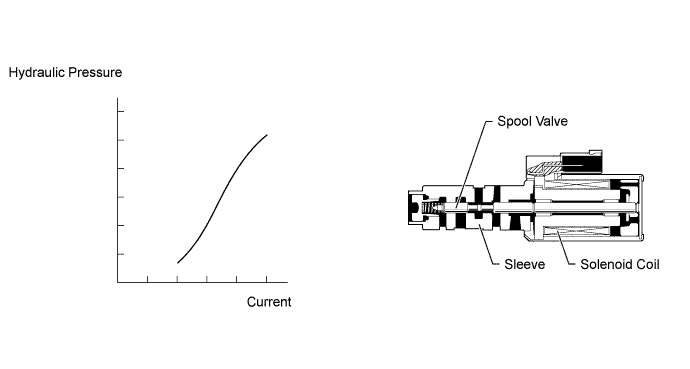

The amount of current flow to the solenoid is controlled by the ECM. During the lock-up operation, if the current increases, the lock-up hydraulic pressure increases.

| DTC Code | DTC Detection Condition | Trouble Area |

| P2759 | Open or short is detected in the shift solenoid valve SLU circuit for 1 second or more while driving (1-trip detection logic). |

|

MONITOR DESCRIPTION

When an open or short in the shift solenoid valve SLU circuit is detected, the ECM determines that there is a malfunction. The ECM will illuminate the MIL and store the DTC.MONITOR STRATEGY

| Related DTCs | P2759: Shift solenoid valve SLU/Range check |

| Required sensors/Components | Shift solenoid valve SLU |

| Frequency of operation | Continuous |

| Duration | 1 second |

| MIL operation | Immediately |

| Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

| The monitor will run whenever the following DTCs are not present | None |

| Solenoid current cut status | Not cut |

| Battery voltage | 11 V or more |

| Ignition switch | ON |

| Starter | OFF |

TYPICAL MALFUNCTION THRESHOLDS

| Solenoid status from MIC | Failure |

COMPONENT OPERATING RANGE

| Output signal duty | Less than 100% |

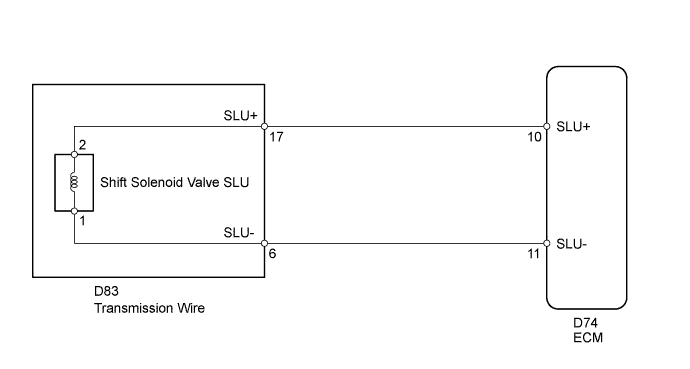

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Perform the universal trip to clear permanent DTCs (Click here).

| 1.INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SLU) |

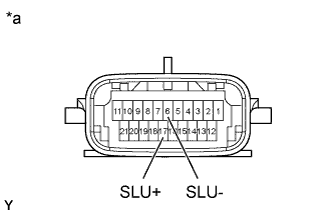

Disconnect the D83 transmission wire connector.

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 17 (SLU+) - 6 (SLU-) 20°C (68°F) 5.0 to 5.6 Ω 17 (SLU+) - Body ground Always 10 kΩ or higher 6 (SLU-) - Body ground Always 10 kΩ or higher

Text in Illustration *a Component without harness connected

(Transmission Wire)

|

| ||||

| OK | |

| 2.CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM) |

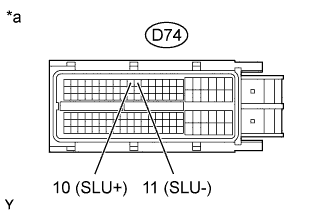

Disconnect the D74 ECM connector.

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition D74-10 (SLU+) - D74-11 (SLU-) 20°C (68°F) 5.0 to 5.6 Ω D74-10 (SLU+) - Body ground Always 10 kΩ or higher D74-11 (SLU-) - Body ground Always 10 kΩ or higher

Text in Illustration *a Front view of wire harness connector

(to ECM)

|

| ||||

| OK | ||

| ||

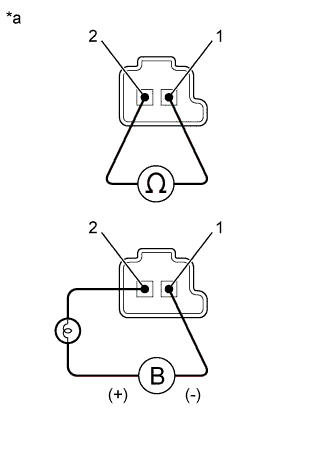

| 3.INSPECT SHIFT SOLENOID VALVE SLU |

Remove shift solenoid valve SLU.

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 5.0 to 5.6 Ω

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition Specified Condition - Battery positive (+) with a 21 W bulb → Terminal 2

- Battery negative (-) → Terminal 1

Valve moves and makes an operating noise - Battery positive (+) with a 21 W bulb → Terminal 2

| *a | Component without harness connected (Shift Solenoid Valve SLU) |

|

| ||||

| OK | ||

| ||