DRIVE BELT > INSTALLATION |

for Preparation Click here

| 1. INSTALL V-RIBBED BELT |

Install the belt.

| 2. ADJUST V-RIBBED BELT |

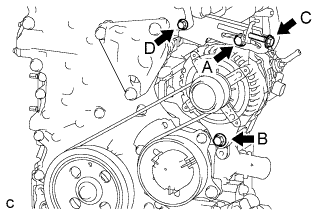

Turn bolt C to adjust the tension of the V-ribbed belt.

|

Tighten bolts A and B.

- Torque:

- Bolt A:

- 19 N*m{ 190 kgf*cm , 14 ft.*lbf }

- Bolt B:

- 43 N*m{ 438 kgf*cm , 32 ft.*lbf }

- NOTICE:

- Confirm that bolt D is not loosened.

| 3. INSPECT V-RIBBED BELT |

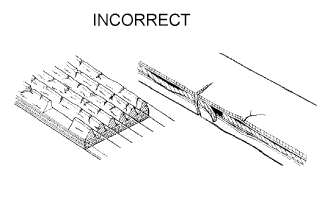

Check the belt for wear, cracks or other signs of damage.

If any of the following defects is found, replace the V-ribbed belt.- The belt is cracked.

- The belt is worn out to the extent that the cords are exposed.

- The belt has chunks missing from the ribs.

- The belt is cracked.

|

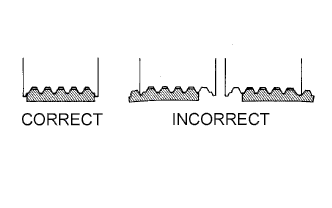

Check that the belt fits properly in the ribbed grooves.

- HINT:

- Check with your hand to confirm that the belt has not slipped out of the groove on the bottom of the pulley. If it has slipped out, replace the V-ribbed belt. Install a new V-ribbed belt correctly.

|

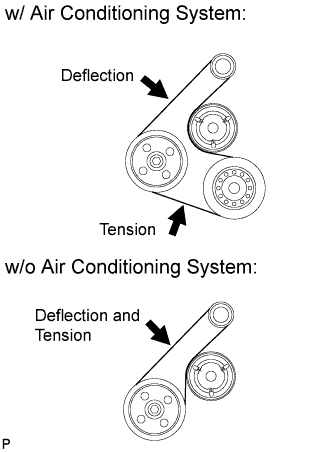

Check the V belt deflection and tension.

- Deflection:

Item Specified Condition New belt 7.0 to 8.2 mm (0.276 to 0.323 in.) Used belt 7.6 to 10.0 mm (0.299 to 0.394 in.)

- Tension:

Item Specified Condition New belt 700 to 800 N (71 to 82 kg, 157 to 180 lb) Used belt 550 to 750 N (56 to 77 kg, 124 to 169 lb)

- HINT:

- When inspecting the V belt deflection, apply 98 N (10 kgf) tensile force to it.

- After installing a new belt, run the engine for approximately 5 minutes and then readjust the tension to (new belt) specifications.

- Check the V-ribbed belt deflection and tension at the specified point.

- V-ribbed belt tension and deflection should be checked after 2 revolutions of the engine.

- V-ribbed belt tension and deflection should be checked at TDC crank angle and cold condition.

- When adjusting a belt, adjust its deflection and tension to the intermediate values of the specification.

- When reinstalling a belt which has been used for over 5 minutes, adjust its deflection and tension to the used belt specification.

- When using a belt tension gauge, confirm its accuracy by using a master gauge first.

- If using a sonic tension meter:

- Weight:

- 15 g/rib*m

- Width:

- 6 ribs

- Span:

- 188 mm (7.40 in.) (w/ air Conditioning)

- 282 mm (11.1 in.) (w/o air Conditioning)

|

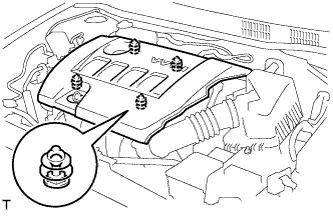

| 4. INSTALL ENGINE UNDER COVER RH |

| 5. INSTALL NO. 2 CYLINDER HEAD COVER |

Engage the 4 clips to install the No. 2 cylinder head cover.

- NOTICE:

- Be sure to engage the clips securely.

- Do not apply excessive force or do not hit the cover to engage the clips. This may cause the cover to break.

|