SFI SYSTEM > Fuel Injector Circuit |

for Preparation Click here

DESCRIPTION

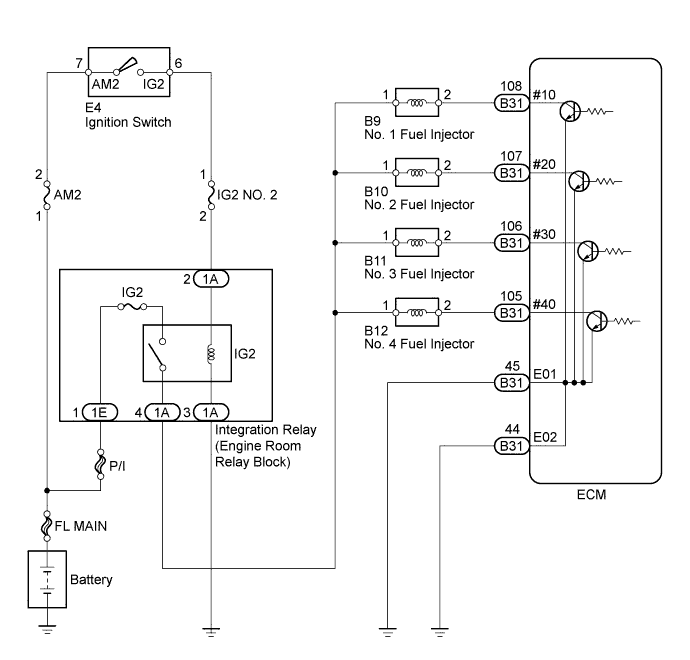

The fuel injectors are located on the intake manifold. They inject fuel into the cylinders based on the signals from the ECM.WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

| 1.INSPECT FUEL INJECTOR (POWER SOURCE) |

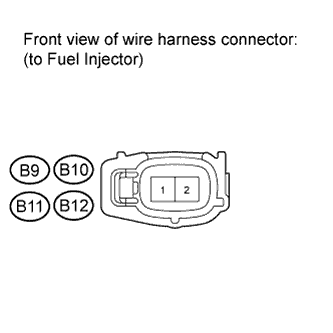

Disconnect the fuel injector connectors.

|

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Switch Condition Specified Condition B9-1 - Body ground Ignition switch ON 11 to 14 V B10-1 - Body ground Ignition switch ON 11 to 14 V B11-1 - Body ground Ignition switch ON 11 to 14 V B12-1 - Body ground Ignition switch ON 11 to 14 V

Reconnect the fuel injector connectors.

|

| ||||

| OK | |

| 2.INSPECT FUEL INJECTOR (INJECTOR RESISTANCE) |

Inspect the fuel injector (Click here).

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (FUEL INJECTOR - ECM) |

Disconnect the ECM connector.

Disconnect the fuel injector connectors.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Condition Specified Condition B9-2 - B31-108 (#10) Always Below 1 Ω B10-2 - B31-107 (#20) Always Below 1 Ω B11-2 - B31-106 (#30) Always Below 1 Ω B12-2 - B31-105 (#40) Always Below 1 Ω

- Standard Resistance (Check for Short):

Tester Connection Condition Specified Condition B9-2 or B31-108 (#10) - Body ground Always 10 kΩ or higher B10-2 or B31-107 (#20) - Body ground Always 10 kΩ or higher B11-2 or B31-106 (#30) - Body ground Always 10 kΩ or higher B12-2 or B31-105 (#40) - Body ground Always 10 kΩ or higher

Reconnect the fuel injector connectors.

Reconnect the ECM connector.

|

| ||||

| OK | |

| 4.CHECK HARNESS AND CONNECTOR (ECM - BODY GROUND) |

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Condition Specified Condition B31-45 (E01) - Body ground Always Below 1 Ω B31-44 (E02) - Body ground Always Below 1 Ω

Reconnect the ECM connector.

|

| ||||

| OK | |

| 5.INSPECT FUEL INJECTOR (INJECTION AND VOLUME) |

Check the fuel injector injection and volume (Click here).

|

| ||||

| OK | ||

| ||

| 6.CHECK HARNESS AND CONNECTOR (FUEL INJECTOR - INTEGRATION RELAY) |

Disconnect the fuel injector connectors.

Remove the integration relay from the engine room relay block.

Disconnect the integration relay connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Condition Specified Condition B9-1 - 1A-4 Always Below 1 Ω B10-1 - 1A-4 Always Below 1 Ω B11-1 - 1A-4 Always Below 1 Ω B12-1 - 1A-4 Always Below 1 Ω

- Standard Resistance (Check for Short):

Tester Connection Condition Specified Condition B9-1 or 1A-4 - Body ground Always 10 kΩ or higher B10-1 or 1A-4 - Body ground Always 10 kΩ or higher B11-1 or 1A-4 - Body ground Always 10 kΩ or higher B12-1 or 1A-4 - Body ground Always 10 kΩ or higher

Reconnect the fuel injector connectors.

Reconnect the integration relay connector.

Reinstall the integration relay.

|

| ||||

| OK | ||

| ||